China Aluminum Processing Industry 2022 Market Outlook and Investment Research Report

Source: Reproduced from https://www.albiz.cn/

Profile:

Aluminum processing, processing aluminum billet ingots into materials with plastic processing methods, the main methods are rolling, extrusion, drawing and forging. In recent years, China's aluminum processing industry is facing gradually tightening policies, declining profitability and trade friction, etc., to accelerate the transformation and upgrading of the development of the aluminum processing industry has become the top priority.

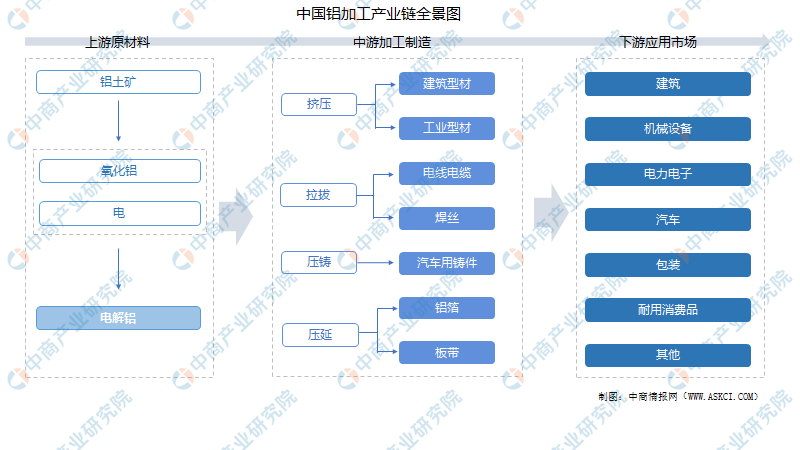

I. Aluminum processing definition and industry chain

Aluminum processing, using plastic processing methods to process aluminum billet ingots into materials, the main methods are rolling, extrusion, drawing and forging. China built a large aluminum processing plant in the mid-1950s, forming a more complete industrial chain. Besides, the product has been serialized into seven alloy systems which could be made into plates, strips, foil, tubes, bars, profiles, wire and forgings (free forgings, die forgings) eight types of products.

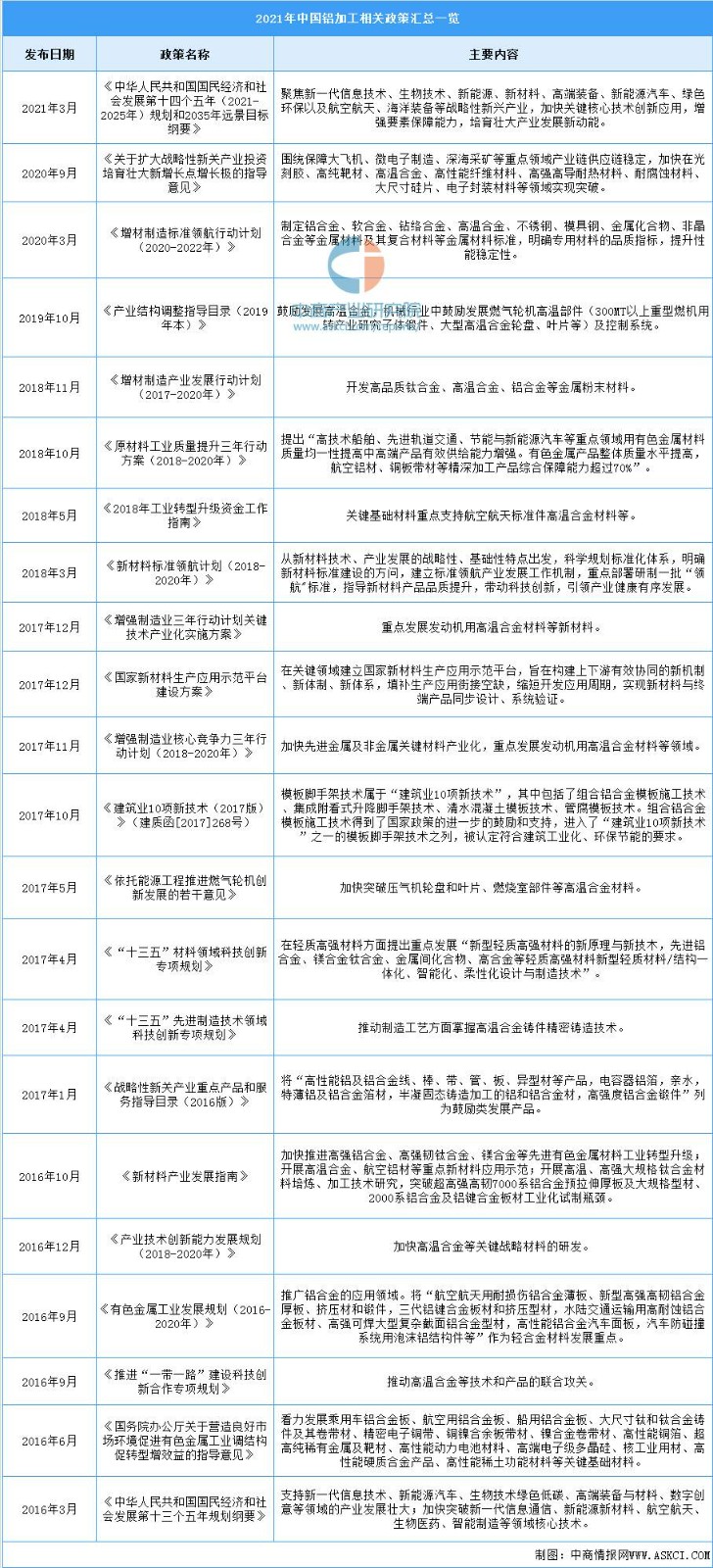

II. Aluminum processing industry development policy

Aluminum processing industry in China has received great attention from governments at all levels and key support from the national industrial policy recent years. The country has issued a number of policies one after another to encourage the development and innovation of the aluminum processing industry, "Additive Manufacturing Standard Pilot Action Plan (2020-2022)" "Guidance on Expanding Investment in Strategic Emerging Industries to Foster and Grow New Growth Points Growth Poles" "New Material Standard Pilot Plan (2018-2020)" and other industrial policies have provided a clear and broad market prospect and provide a good production and operation environment for enterprises. The details are listed as follows.

III. Current development of the aluminium processing industry

Aluminum processing is the processing of aluminum, the raw material electrolytic aluminum through melting, rolling, extrusion and surface treatment and other processes and procedures, the production of aluminum profiles, tubes, bars and other extruded materials, plates, strips, foil and other flat-rolled materials, as well as casting materials and other types of aluminum.

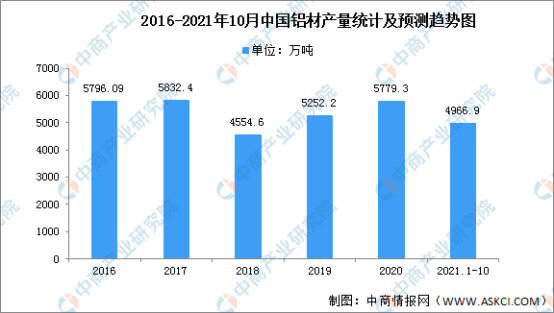

1. Aluminium material

Recent years, China's aluminum processing industry has faced problems such as gradually tightening policies, declining profitability and constant trade frictions. With the country's supply-side structural reform of the aluminum processing industry, technological progress in the aluminum processing industry, aluminum smelting industry has been developing towards high quality. China's aluminum production reached 49.669 million tons by October 2021, up 9.3% year-on-year.

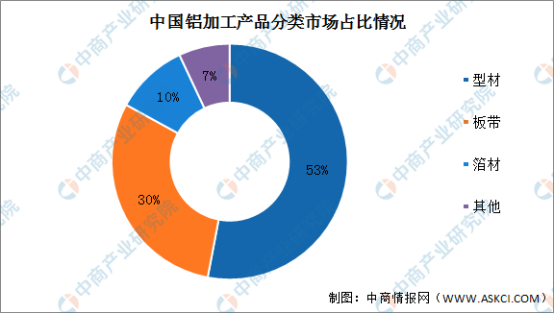

2. Market share

Looking at the structure of aluminum in China, the highest proportion of aluminum profiles is 53%, followed by aluminum sheet and strip and foil in order of 30% and 10% respectively.

3. Market segmentation

(1) Aluminum sheet and strip

With the booming development of downstream industries such as transportation and construction, the market size of China's aluminum processing industry is growing rapidly, with the total output of aluminum sheet and strip in China being about 11.4 million tons in 2017 and 11.9 million tons in 2020, with a compound annual growth rate of 1.44%. It is expected that the output of aluminum sheet and strip in China will reach 12.3 million tons in 2022.

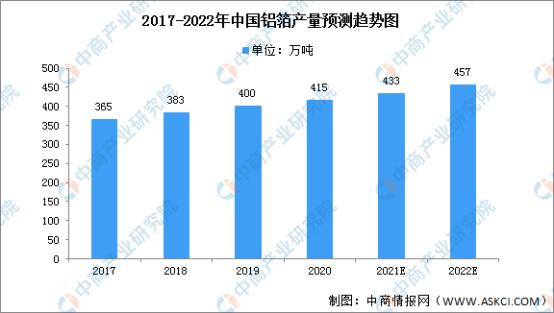

(2) Aluminum foil

Data show that China's aluminum foil production increased from 3.65 million tons in 2017 to 4.15 million tons in 2020, with an average annual compound growth rate of 2.53%. China Business Industry Research Institute predicts that China's aluminum foil production will reach 4.57 million tons in 2022.

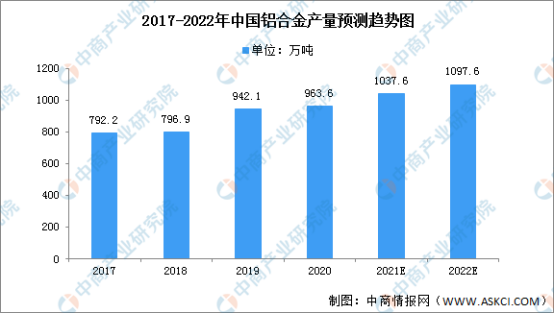

(3) Aluminum alloy

Aluminum alloy has a series of excellent characteristics, such as easy processing, light quality, good electrical conductivity, etc., and its relatively low cost makes it an alternative to steel, copper and other materials. Data show that China's aluminum alloy production fluctuates more obviously, but the overall growth trend is maintained, and the cumulative output of China's aluminum alloy will be 9.636 million tons in 2020, with a compound annual average growth rate of 6.75% from 2017 to 2020, and the output of aluminum alloy is expected to reach 10.976 million tons in 2022.

(4) Aluminium profiles

Aluminum profiles are mainly used in the construction field and industrial field, and can be divided into two categories: construction profiles and industrial profiles. Construction profiles are mainly used in the construction and real estate industries, and among the sub-species consumption fields of construction aluminum profiles, aluminum alloy doors, windows and curtain wall profiles account for the main part of them. Industrial aluminum profiles are mainly used in the four fields of transportation, mechanical and electrical equipment, durable goods and electronic appliances.

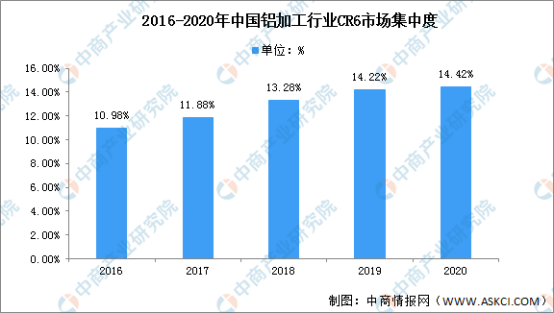

4. Market concentration

The overall concentration of the aluminum processing industry is low, but the CR6 of the aluminum processing industry has been on a growth trend from 2016-2020, growing from 10.98% in 2016 to 14.42% in 2020.

IV. Key players in the aluminium fabrication industry

1. Aluminium China

Aluminum Corporation of China Limited was incorporated on September 10, 2001, and its main business includes: exploration and mining of bauxite resources; production and sales of alumina, primary aluminum, aluminum alloy and carbon, etc.. The company is a national enterprise technology center and has independently developed a large number of representative scientific and technological achievements in bauxite, alumina, fine alumina and electrolytic aluminum.

2. Mingtai Aluminum

Ltd. was established in 1997, and has been deeply engaged in aluminum processing for 20 years. Mingtai's products cover 8 series of specifications such as 1 series, 2 series, 3 series, 4 series, 5 series, 6 series, 7 series, 8 series aluminum alloy, etc. The main products are CTP/PS plate base, aluminum foil for electrolytic capacitor apparatus, single zero foil, double zero foil blank, electronic foil, alloy material, deep-drawn material, brazed plate and medium thick plate.

3. Dingsheng New Material

Jiangsu Dingsheng New Energy Materials Co., Ltd. is located in Jingkou Industrial Park, Zhenjiang, Jiangsu Province, and was incorporated in August 2003. The company's leading products are aluminum sheets, strips, foils and coated materials, as well as deep-processed products such as aluminum oxide sheets and many other series of aluminum products. They are widely used in green packaging, household, home appliance, electronic communication, transportation, printing, chemical, building materials, decoration and other industries.

4. Tianshan Aluminum

Tianshan Aluminum Co., Ltd. was located in the Chemical New Materials Industrial Park of Shihezi Economic and Technological Development Zone in August 2010. The main business of Tianshan Aluminum Group Co., Ltd. is the production and sale of primary aluminum, alumina, high purity aluminum, pre-melted anodes and aluminum deep processing products and materials. Tianshan Aluminum is building a new alumina production line with an annual capacity of 2.5 million tons in Jingxi, Guangxi, a new pre-baked anode production line with an annual capacity of 500,000 tons in the national economic development zone in Alar, Aksu, Xinjiang, and a new high purity aluminum production line of 60,000 tons in Shihezi, Xinjiang.

5. Nanshan Aluminum

Ltd. was successfully listed on the Shanghai Stock Exchange on December 23, 1999. Since its listing, the company has gradually formed a complete aluminum industry chain from energy, alumina and electrolytic aluminum to aluminum profiles and high-precision aluminum plates, strips and foils.

V. Prospects for the development of the aluminium processing industry

1. National economic development drives industry progress

Economic development to promote people's pursuit of high-quality life, as a modern economy and high-tech development pillar of the demand for aluminum raw materials is expected to be greater expansion, the rapid development of the building curtain wall, transportation, electric power equipment, national defense, high-end equipment, packaging and other industries, will make aluminum processing material consumption continues to grow, at the same time, the state vigorously advocate the expansion of aluminum instead of steel, copper, wood, paper, plastic and other non-environmental protection The application of energy-saving materials, new products, new processes, new uses of aluminum processing materials will continue to emerge, thus promoting the technological progress of the industry and the sustainable and healthy development of the industry.

2. Industrial technology upgrade to promote the development of the industry

The quality of aluminum ingots has improved in the direction of large specifications and high uniformity; the process equipment has been updated in the direction of short process and automation; the rolling technology has been innovated in the direction of rapid deformation, large deformation and high precision. Together with the continuous optimization of mold design and processing methods, the comprehensive performance and service life of materials have been greatly improved, and high-tech products are emerging.

3. The expansion of aluminum alloy application fields boosts the development of the industry

Aluminum alloy is the most widely used non-ferrous metal structural material in the industry, and the aluminum alloy industry has developed into a relatively mature market. In today's low-carbon economy has become the trend, due to the increase of market demand and the improvement of aluminum processing technology, the application of aluminum alloy in new energy vehicles, high-speed rail, ships, aviation and other high-end fields is also becoming more and more extensive. In the future, the application field of aluminum alloy in China will continue to expand and further promote the sustainable development of aluminum processing industry.

Sichuan Tianyue has been specialising in the customisation of curved and shaped ACP for many years, with exquisite skills and wide acclaim.

Contact ( For Quotation): +86 18566072015

Email Address: support@tianzhiyue.com.cn